- Over 25 years of experience in the field of polystyrene reaction technology

- More than 25 installed reactors for GPPS and HIPS plants all over the world

- Key equipment/technology packages comprising:

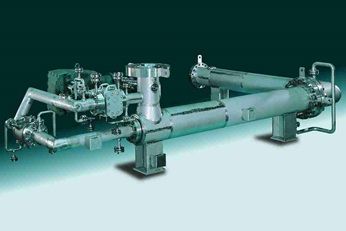

- SMR™ Continuous Post Polymerization Reactors

- Devolatilization Technology able to produce Polystyrene with the lowest residual volatile content in the Industry

- Upgrading technology with SMX or SMX plus mixer, with the lowest possible pressure drop, suitable for mixing fluids with viscosity differences of more than 1:1 000 000

Polystyrene (PS)

Enhance the quality of polystyrene

- For Polystyrene (PS)

Sulzer expertise

Sulzer has over 25 years of experience in providing key equipment and technology for a wide range of polystyrene production plants (GPPS/HIPS and swing plants), with capacities from 28 000 t/a to 200 000 t/a per single train.

Benefits of Sulzer reactors

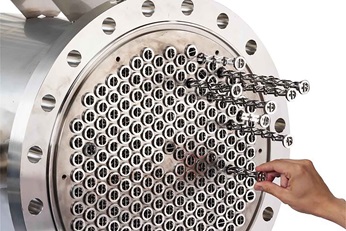

Sulzer Mixer Reactors (SMR™) are currently used all over the world, with capacities up to 100 000 t/a per line. The simplicity of the technology allows the highest levels of polymer conversion in the industry with minimum maintenance requirement (no moving parts). As a result, Sulzer has become a leading provider of high-performance key technology to the polystyrene market.

By retrofitting GPPS/HIPS plants with Sulzer key technology, your plant will achieve higher capacity and improved product quality.

Devolatilization technology

Sulzer's devolatilization technology enables your process to achieve the lowest levels for residual volatiles, while meeting the most stringent environmental standards.

Sulzer mixing process

Sulzer offers the most efficient mixing process on the market for all kinds of additives in polymer melts. It is based on our latest SMX plus mixing technology, with a 50% pressure drop reduction compared to our classic SMX mixer.

Contact our Polymer team below