- Excellent plug flow behavior and narrow residence time distribution

- Well-defined mixing and small reaction volume due to high driving forces for reaction

- Low shear thus gentle product treatment

- No hot spots and no dead zones

- High flexibility with regard to operation and down-turn

- Fast product transition and fast change of process conditions

- Safety and environmental friendliness inherent to the design

- No rotating parts and minimal maintenance costs

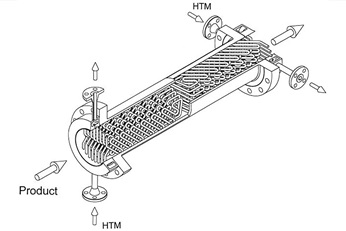

Heat exchanger SMR

Be in control where mixing meets heat transfer

The Sulzer Mixer Reactor SMR™ is a tube bundle heat exchanger that allows high-effective cooling or heating of viscous media. The SMR heat exchanger is your first choice if you wish to combine effective mixing with controlled heat transfer.

- For high-effective heating or cooling of viscous media

- Polymer industry

- Fiber industry

Key characteristics

The SMR reactor consists of a series of specially configured tube bundles. They are positioned perpendicular to each other, which enhances radial mixing across volume highly packed with heat transfer surface area. Water, steam, thermal oil, or other special cooling media can be used as heat transfer fluid. Each bundle can be designed to feature different mixing and heat transfer effects in order to meet stringent process requirements.

Technical specification

| Diameter | from 80 – 1600 mm, larger units upon request |

| Length | determined by process requirements and requested performance, ranges from 1 m for a compact heat exchanger up to 20 m for a full reactor tower |

| Standard material | Stainless steel / carbon steel |

| Special surface coatings | on request (i.e. for food applications) |

| Design | Welded mono-block is common. Flanged design is recommended if process routine requests periodic removal and disposition of bundles |