- High and controllable heat transfer rates

- High conversion and reduction of by-products

- No inert system or solvents required

- Consistently uniform product quality through excellent control of temperature-time history

- Suppression of side reactions

- No dead zones, thus facilitating a fast transition of products and process conditions

- No rotating parts, thus minimized maintenance costs

- Low energy consumption, therefore overall low operating costs

Polymer production

Smooth and efficient heat transfer solutions for polymer production

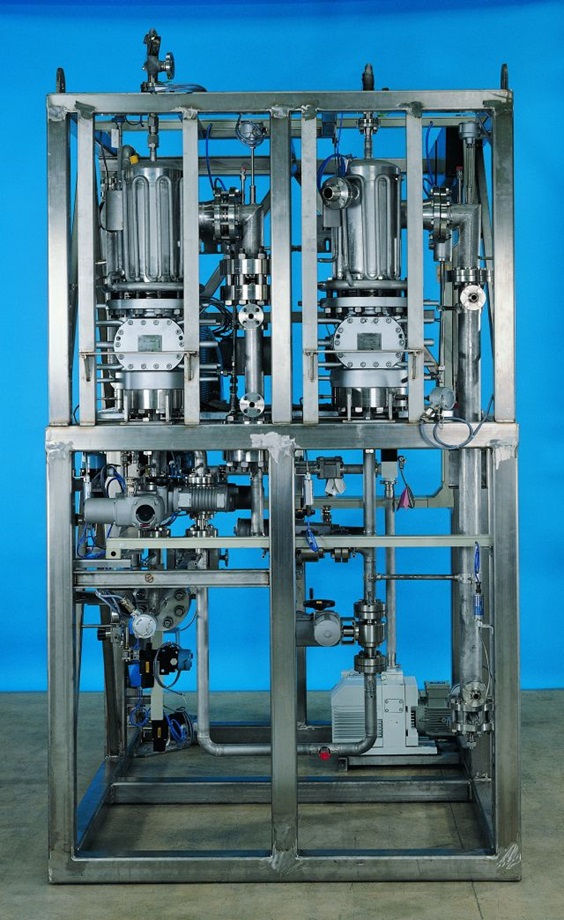

Sulzer has been providing key components and skid-mounted systems for the production of various kinds of polymers for over two decades.

- Polystyrene (PS)

- Poly lactic acid (PLA)

- Expandable polystyrene (EPS)

- Devolatilization

Key components

Key components of our technology packages for polymer production

- SMX, SMX plus, SMV, CompaX static mixers for

- Admixing of catalysts and initiators in reaction solutions

- Admixing of low-viscosity additives in polymer melt

- Admixing of masterbatch into polymer melt

- Blending/compounding of two polymers

- Dispersing of non-soluble components in polymer melt

- Homogenizing of polymer melt

- SMR heat exchanger / reactors for

- Exothermic reaction

- Loop reaction

- Plug flow reaction

- Cooling of polymer melt

- Exothermic reaction

- SMXL heat exchangers for

- Devolatilization of polymers

- Heating of polymer solutions

Complete systems are available for the production of

- EPS (Expandable polystyrene)

- PLA (Polylactic Acid)

Polymer application range

We offer you components for processing the following polymers

- Adhesives

- Cellulosic fibers

- EPM/EPDM

- EPS

- LLDPE, LDPE, HDPE

- PBT, PB, PBS, PIB

- PET

- PLA

- PMMA

- Polyamide (PA, PA6)

- Polycarbonate

- Polypropylene

- PP

- POM

- PS (GPPS/HIPS)

- PUR

- PVAC

- SAN/ABS

- Silicon elastomers

- Silicon oils

- Silicon polymers

- Viscose

Reaction technology

Reaction technology

- Fast transition time due to outstanding plug flow behavior and thus high yield and productivity

- Easy control of exothermic reactions due to extensive, volume-independent heat transfer surface, even at large scales, resulting in high operational safety, also in critical situations (for example, power outage)

- Safe operation (no gas phase, thus no explosion risks in the equipment)

- Low shear rates and thus reduced product degradation (allows, for example, for very high rubber efficiency in impact-strengthened polymers)

- No maintenance due to absence of moving parts means reduced operating costs

Devolatilization technology

Devolatilization technology

- Lowest residual monomer content (lower entry barrier for food applications)

- Simple with a minimum of rotating equipment, and therefore easy to maintain with low operating costs

- Efficient and thus low energy consumption for reduced operating costs

- Gentle product handling allowing for highest product quality (lowest oligomer content, optimum transparency, no black spots) to achieve best prices in the market

Mixing

Mixing of additives in polymer melt

- Most energy efficient (one order of magnitude lower than dynamic systems) saves you operating costs

- Highly reproducible quality due to well defined mixing patterns minimizes the downtime of your plant

- No maintenance due to absence of moving parts reduces your running costs

Contact our Polymer team below