- Studies support your decision-making process

- Studies for developing and defining the separation process

- Studies for implementing new processes, new products or adapt to changed conditions

Studies and conceptual designs

Helping you answer all those upfront questions

- Process development study

- Feasibility study

- Conceptual engineering study

- Energy savings study

- Debottlenecking study

Reasons for a study

At the start of a project, usually not all conditions for a separation process are clearly defined, and several questions often have to be answered before the best technology can be chosen. For existing plants, changes in the process conditions, requirements for different throughput or energy optimization may often be solved by the addition of other unit operations. We support you in the decision process by conducting one or more studies, for example:

- Process development study – a study to support you in the development of the separation part of a new process

- Feasibility study – a study to investigate different approaches to a given separation task

- Conceptual engineering study – a study to develop in more detail a separation process to support, for example, cost estimation

- Energy savings study – a study to evaluate possibilities for energy savings and change in utilities specifications

- Debottlenecking study – a study to evaluate possible bottlenecks for a planned capacity increase, or to identify reasons for a reduced performance

Basis

The basis for a study is initially the description of a separation task, or the expected improvements. Requirements at your end might be newly developed products and processes, or new process conditions for an existing process, for example. We can also provide you with support if the exact details and challenges of the separation task are not yet known to you, for example, by performing theoretical investigations (process simulations), or experimental examinations in our test centers.

Broad range of unit operations

Complex separation tasks often require the use of different separation technologies to achieve an optimum and energy efficient process. Our expertise covers our full and unique range of the following main separation technologies:

- Distillation

- Absorption

- Liquid-liquid extraction

- Membrane processes, including vapor permeation and pervaporation

- Film evaporation

- Layer and suspension crystallization

Our extensive technology portfolio ensures that you will be proposed the best technology, or the optimum combination of different technologies as a solution to your separation task. In particular, the possibility of combining different technologies in a so-called hybrid process solution is a unique advantage for our customers, and often the only option to further improve an already optimized process.

Tools

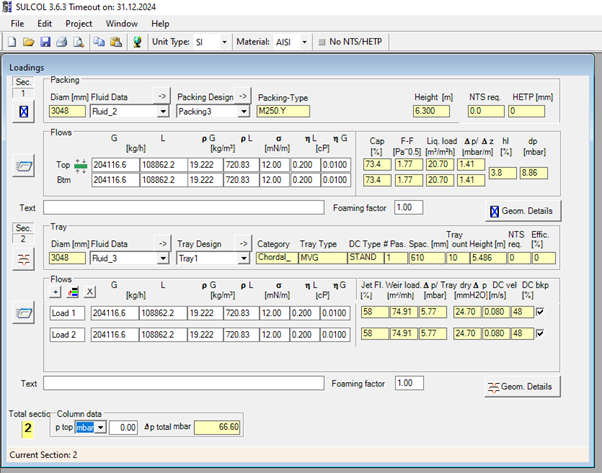

The separation process is calculated using up-to-date simulation tools. The basic data for these calculations are provided by you, the customer, or are taken from literature, data banks or from our large collection of data based on our experience. Pilot tests in our test centers can also be used to provide additional data, especially for customer-specific components.

Verification of study findings

Depending on the available data and required assumptions, the results of the study can be verified with the help of tests that are performed in our test centers. Test samples supplied by you will be used for these tests, therefore ensuring the reliability of the proposed process solution in comparison with the test results.

Outcome of a study

The study will provide you with all the information you require to decide on the next step in your project. We will present the best technology for your separation task including information about expected product purity, energy consumption, and investment costs for our products. The findings of the study will be summarized in a report, which will typically contain:

- Design basis and assumptions

- Process description

- Simplified process flow diagram (from the simulation tool)

- Main process data

- Main energy consumption figures

- List of key equipment

- Recommendations

Examples

Typical examples of studies are:

- Product purification by distillation

- Energy reduction for distillation processes

- Optimum separation sequence for multi-component mixtures

- Conventional distillation versus vapor-recompression distillation

- Combination of fractional crystallization and distillation

- Combination of distillation and membrane processes

- Suitable entrainer for azeotropic and extractive distillation

- Extraction versus conventional azeotropic distillation

- Reactive distillation processes