- Unrivaled predictions. With combined physics and statistics based models, take anomaly detection to the next level.

- Beyond digital. Leverage your Sulzer engineers to take actions faster, with in-depth analysis of your pump systems’ performance.

- One platform. Full visibility of what matters, wherever you are. All your pumps’ critical data focused into one comprehensive overview.

BLUE BOX™ - your collaborative digital solution

Turn your pump data into value!

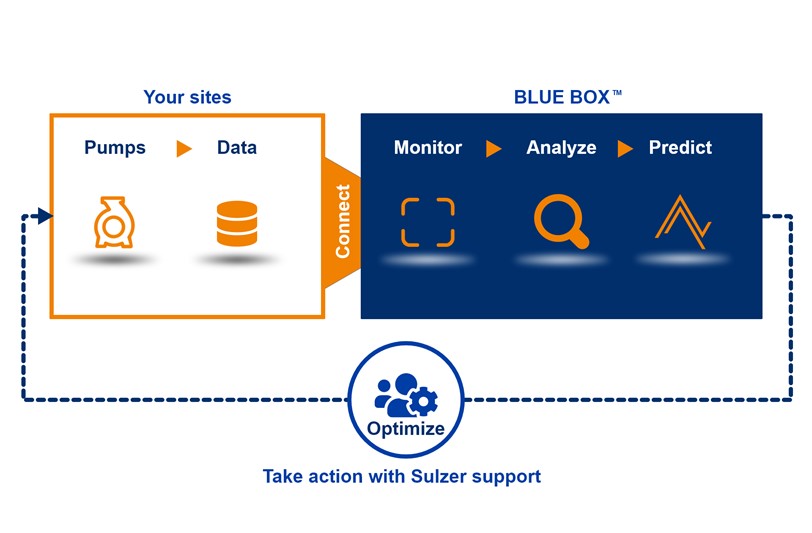

Connecting your data with Sulzer’s pump expertise

How do we work together? Data is transferred as a one-way push from your data collection system to Sulzer’s secure cloud environment, hosted on Microsoft Azure. This information is presented to you via a series of screens highlighting analytical insights. Designed to have minimal impact on your IT/OT environment, BLUE BOX complements your condition monitoring investment.Define the status of every pump, at any moment

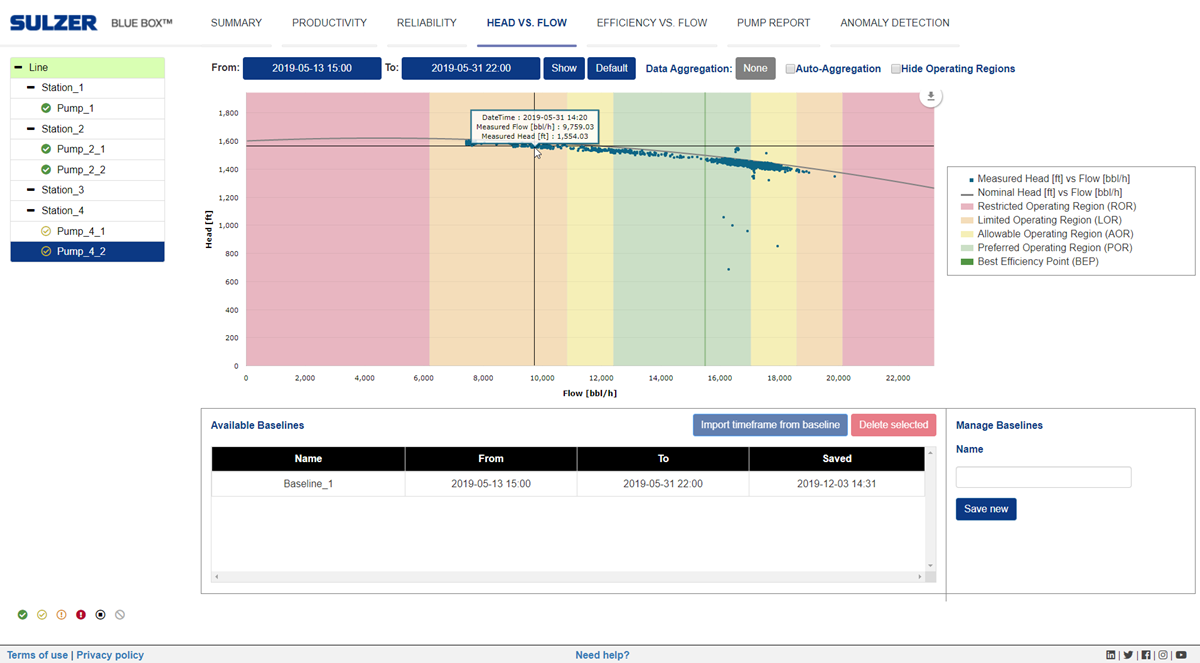

Visualize your entire pumping system and drill down into the details. Immediately highlight under-performing and potentially unreliable assets while identifying opportunities to reduce operational risk and energy consumption.

Evaluate operational impact on your assets

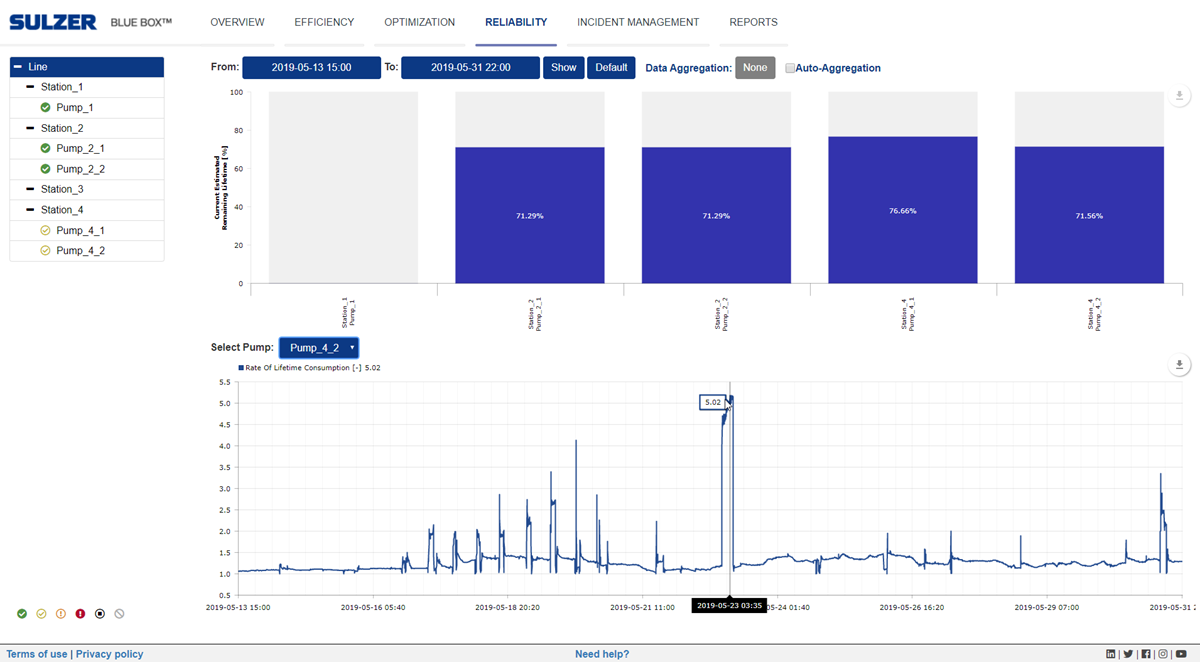

BLUE BOX offers performance and reliability metrics for assessing the impact of your current and historical operation. Features include:

- Sulzer recommended operating regions

- Energy and money wasted

- Rate of lifetime consumption

The software quickly identifies and highlights under-performing assets to minimize downtime, improve overall performance and process safety.

Predict imminent failures and identify abnormal operation

Take full control of your pump maintenance. BLUE BOX anomaly detection provides accurate predictions, giving you more time to plan maintenance activities. This goes beyond traditional threshold alerting, utilizing modern machine learning techniques to identify developing failures. Further to this, we enrich our data-driven methods with Sulzer’s physical modeling, based upon decades of engineering expertise.

We train our models with your data. Aligning with your specific needs and continuously evaluating the operating conditions of your assets. The BLUE BOX advises on pump operational behavior, allowing for more targeted maintenance planning.

Get in touch with us

Digital Solutions Team