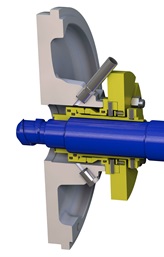

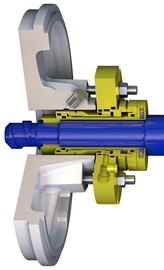

- The cartridge seal forms one solid unit having its own sleeve, fixing flange, seal faces, springs and all necessary O-rings, gaskets, setting clips and fixing crews.

- By the setting clips, the cartridge seal is set radially and axially in the right location during assembly.

Cartridge seals

TS mechanical seals for reliable operation and fast and easy maintenance

TS1, TS2 and TS2P cartridge seals are designed as universal shaft seals for the seal chamber of the standard gland packing casing cover and for the standard shaft sleeve of the gland packing.

- The seal is fixed on the pump shaft or on the shaft sleeve by set screws and into the casing cover by studs and nuts utilizing fixing slots (4x90°) on the seal flange.

- Since cartridge seals can be fitted to the standard casing cover of all kinds of pumps and rotating flow machines, it is possible to use the same seal types in a variety of pumps and other machines.

Technical Specifications Material Alternatives

| TS1 | TS1 with Flushing | TS2/TS2P | |

| P max | 25 bar / 363 psi | 25 bar / 363 psi | 25 bar / 363 psi |

| V max | 25 m/s / 82 ft/s |

25 m/s / 82 ft/s |

25 m/s / 82 ft/s |

T max |

125°C / 257°F |

140°C / 284°F with internal flushing 140°C / 284°F with external flushing |

180°C / 355°F |

| Seal faces |

SiC/SiC, C/SiC | SiC/SiC, C/SiC | SiC/SiC-SiC/SiC SiC/SiC-C/SiC |

| O-rings |

EPDM, FKM | EPDM, FKM | EPDM, FKM |

| Wetted parts |

316 stainless steel (EN 1.4401, EN 1.4436), |

316 stainless steel (EN 1.4401, EN 1.4436), |

316 stainless steel (EN 1.4401, EN 1.4436), |