- Optimization of pump stations

- Flexible maintenance packages providing the best whole life costs

- On-site maintenance and repair

- Site and equipment surveys

- Energy management services

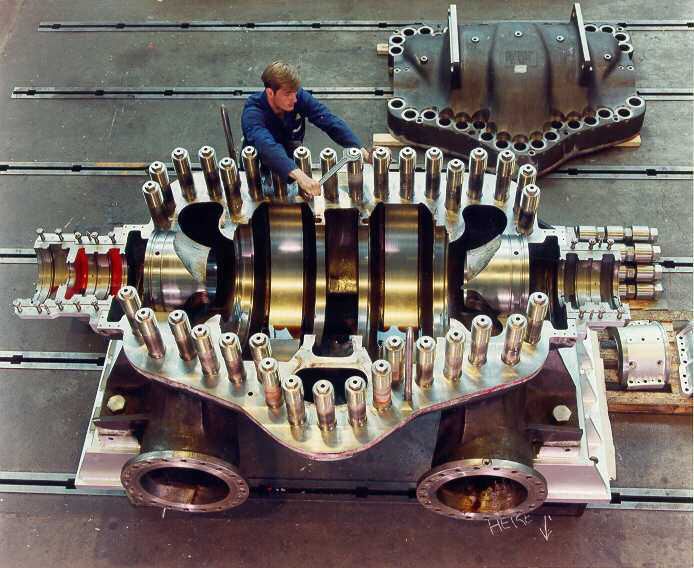

- Refurbishment of pump/stations

- Control, automation and monitoring

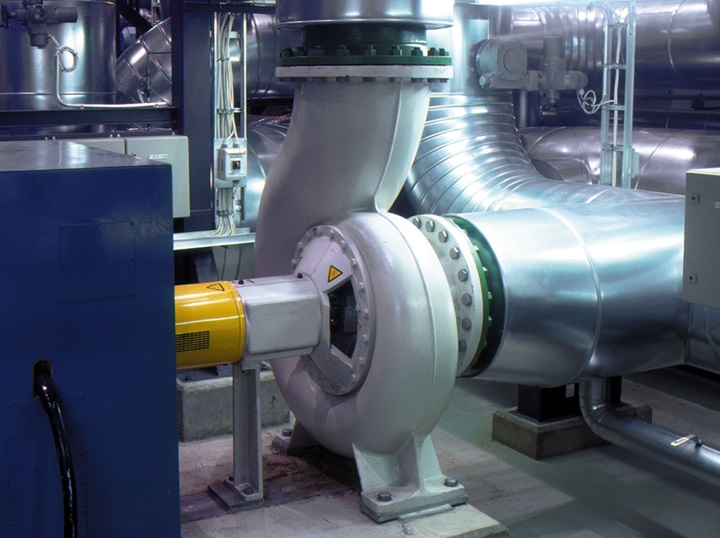

- Onsite installation and commissioning of pumps

- Equipment installation (mechanical)

- Equipment installation (electrical)

- On-site commissioning and testing

- Temporary and hire pumps

Service for water and wastewater pumps

Services for equipment lifetime and economy

As equipment ages, it costs more to run. Spare parts become expensive and lead times longer, while performance falls behind that of the latest products. Sulzer’s technical support staff can help you identify and prioritize replacement or upgrade opportunities, so that you choose the most appropriate equipment at the most appropriate time. Besides recommending and supplying the equipment, we can take full responsibility for its installation and commissioning if desired. We can provide:

- Replacement equipment

- Adapter brackets and guide-rail replacement

- Selection assistance and technical support

- Full contract management

Quality and sustainability

We are committed to providing our customers with the best products at the highest quality standards in the industry. All of our locations around the world implement certified management systems in accordance with ISO 9001 (Quality), ISO 14001 (Environment) and OHSAS 18001 (Health and Safety) as an effective way to sustain the continuous improvement of our processes and products. Some of our locations also have specific certifications, such as IECEx 3.