High velocity oxygen fuel spraying HVOF

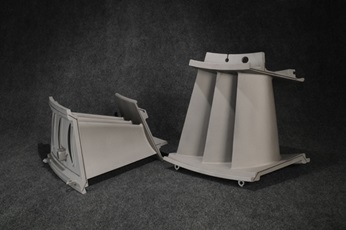

Increased wear resistance for larger parts

HVOF coating is a high-velocity, low-temperature spraying process used for the production of metallic and hard facing coatings. Sulzer has well-equipped locations worldwide for all kinds of coating. We help you protect your components against wear.

High Velocity Oxygen Fuel (HVOF) spraying is a group of thermal spraying processes which spray flames at supersonic speeds. The detonation gun (D-gun) process was the first type of HVOF process used.

In HVOF processes, kinetic energy of particles is more important than temperature. These processes use high-impact energy to produce dense coatings at relatively low temperatures.

In HVOF spraying, fuel and oxygen are pressed into a combustion chamber in a continuous flow, producing a jet of combustion products at extremely high speed. Powder particles injected into this gas steam are accelerated to a very high velocity. Fusion is obtained by the kinetic impact of the coating particles rather than by their increased temperature: the process is carried out in an ambient atmosphere.

Cleaning and surface preparation are critical and require a well-equipped workshop.

In HVOF processes, kinetic energy of particles is more important than temperature. These processes use high-impact energy to produce dense coatings at relatively low temperatures.

In HVOF spraying, fuel and oxygen are pressed into a combustion chamber in a continuous flow, producing a jet of combustion products at extremely high speed. Powder particles injected into this gas steam are accelerated to a very high velocity. Fusion is obtained by the kinetic impact of the coating particles rather than by their increased temperature: the process is carried out in an ambient atmosphere.

Cleaning and surface preparation are critical and require a well-equipped workshop.

There are different types of HVOF spraying, based on:

- The fuel used: either hydrogen, natural gas, or kerosene

- The oxygen source: either pure oxygen or compressed air

Advantages of HVOF

- Ideal for coating large components

- Relatively cool coating process, due to the brief presence of particles in the hot gas stream

- Can produce high-density carbides without degeneration due to high-temperature effects

HVOF is widely used for the production of high-quality, wear-resistant coatings of carbides and stellites. It is also used to apply MCrAlY coatings, which are alloys of M (Metal = nickel, cobalt, or iron, or a combination), Cr (chromium), Al (aluminum), and Y (yttrium).