- Reliable operation under extreme conditions

- Minimum maintenance is required even during long periods on standby

- Self-contained, containerized module supports a diesel drive, booster pump, hydraulic power unit, fuel system, and all other systems required to operate the unit

- Absence of 90 degree gearboxes for lineshaft pumps or the high-voltage electric cables associated with electro-submersible solutions makes the unit extremely robust in an emergency situation

- Package is designed to produce the full pressure needed at deck level, thus dispensing with the need for a booster

- Absence of 30 – 40 m long lineshafts, with several intermediate bearings, is a key advantage in terms of maintenance and reliability

Diesel hydraulic driven pumping unit for firefighting

Hydraulic fire fighters for extreme conditions

Firewater pumps lie at the heart of a firefighting system. Reliable operation under extreme time conditions is a key requirement. Our self-contained hydraulic drive fire pump system delivers optimum performance and features to ensure minimum maintenance is required due to long periods on standby.

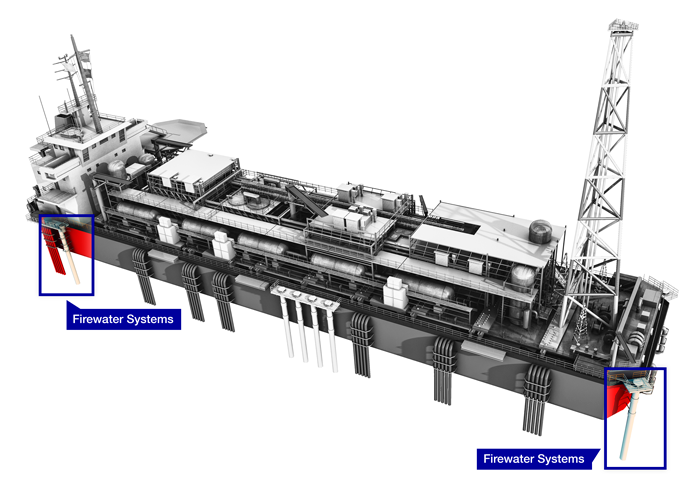

- Floating Production Storage and Offloading (FPSO) unit

- Production platforms

- Drill ships

Main design features

- Heavy-duty marine diesel engine, turbo-charged and after-cooled

- Sulzer-Rexroth design Hydraulic Power Unit (HPU)

- Fire-rated, acoustic insulated container enclosure (A0, A60, H60, H120 ratings)

- Complete dedicated fire detection and extinguishing system (CO2 or water mist)

- Proven design heavy-duty lift and booster pumps in Duplex or Super Duplex stainless steel

Key characteristics

| Capacities | 500 to 3,500 m3/h / 2,200 to 15,500 US gpm |

| Heads | Up to 200 m / 650 ft |

| Pressures | Up to 25 bar / 360 psi |

| Temperatures | Up to 50°C / 122°F |

| Discharge sizes | Up to 500 mm / 20 inches |

| Maximum speed of rotation | Up to 1,800 rpm |