- Long and trusted experience in all industrial segments

- Excellent performance

- Suitable for the most demanding industrial applications

- Unique and superior design features minimize life-cycle costs

- Dense standardization available within the Scaba TreatX concept

- Quick and easy installation, safe operation, easy maintenance and service

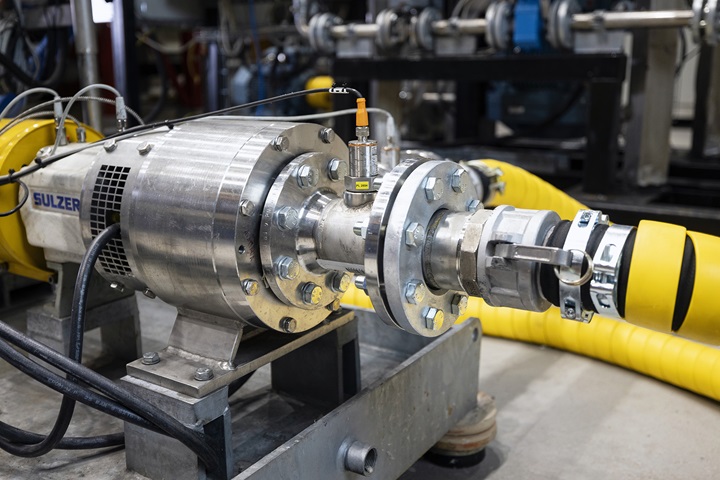

Scaba top mounted agitator

Raise performance with our top-mounted agitators

Scaba top-mounted vertical agitators are used for mixing and agitating process liquids in many industries, including wastewater and industrial applications. They ensure homogenous mixing results, high process reliability, high efficiency, low operating costs and low environmental stress. A comprehensive range of standardized agitators are available within the Scaba TreatX concept, especially suitable for selected applications in water and wastewater industries.

- Mixing in tanks

- Clean and lightly contaminated liquids

- Viscose liquids

- Fibrous slurries

- Slurries

- Solids containing liquids

- Liquids with high gas content

Main design features

- Versatile, reliable, high-efficiency mixing hydraulics and material options

- Reliable and heavy-duty construction

- Modular design minimizes the spare part inventory costs

Key characteristics

| Temperatures | Up to 180 °C / 355 °F |

| Propeller diameter | 100 mm - 6 m / 4 in - 236 in |

| Shaft length | Up to 30 m / 100 ft |

Documents

Brochures

-

SALOMIX and Scaba top-mounted agitatorspdfLanguages:

Case studies

Case studies and articles

-

Scaba agitator for demanding industrial mixing applicationBallarat is a city located at the Yarrowee River in the Central Highlands of Victoria, Australia, with around 101’600 inhabitants. The Ballarat South Wastewater Treatment Plant (BSWWTP) has undergone an AUD 10 million upgrade. A new aeration system was also completed as part of this upgrade and it has helped optimize biological nutrient removal and reduce energy consumption.

-

Reliable Scaba agitators for demanding process applicationsIn 2010, the world’s largest single pulp line with a capacity of 5’000 t/d started in Rizhao. Its wastewater treatment plant was designed and built by Aquaflow (Veolia), and the plant currently operates with an even smaller environmental impact than what the tough Chinese regulations prescribe. To fulfill various applications in the process, Sulzer supplied reliable agitators which minimize both power and chemical consumption.

-

Vienna’s climate-neutral wastewater treatment plant gets efficiency boost with Sulzer technologiesThe E_OS (Energy Optimization through Sludge Treatment) project on the edge of Vienna is a pioneering facility designed to transform the Austrian capital’s wastewater treatment plant from a major energy consumer into a net producer. Important parts of the project therefore include maximizing energy efficiency and optimizing power generation.

-

Scaba heavy-duty agitators save energy in sulphur meltersPhosAgro is the biggest manufacturer of phosphate-based fertilizers in Europe. The largest site is the chemical cluster in Cherepovets, Russia, where the sulphuric acid is locally produced from elementary sulphur. Two new melters were built in an expansion project. It was essential to manage the heat transfer in the melters by agitators to ensure the capacity of the plant.

-

Optimizing the performance of sludge treatment and anaerobic digestion plantsLarge wastewater treatment facilities often incorporate an anaerobic digestion (AD) plant to handle sludge and deliver heat as well as electrical energy to support the operation of the site. Process performance depends on equipment reliability and getting the most out of the feedstock. Improved efficiency enables plants to increase throughput without expanding the site and this can be achieved by optimizing the sludge handling equipment.

-

How to optimize agitatorsSulfuric acid is the key chemical used in the production process of wet phosphoric acid (WPA). Hence, the production of sulfuric acid close to the phosphoric acid plant (PAP) has many advantages. Not only does this reduce transport costs, but the nearby production of sulfuric acid, which is an exothermal process, allows the residual thermal energy to be used for the manufacture of concentrated phosphoric acid. Steam is generated to feed the heat exchanger located within the concentration unit of the phosphoric plant. Read the whole article.

-

Supporting sustainable fuel productionSulzer is at the forefront of engineering excellence and quality, delivering best-in-class solutions to support companies in important growth industries, such as biobased, renewable energy production. Understanding precisely what customers need, as well as maintaining the highest standards in manufacturing and service has led to many significant project wins, not least the collaboration with Inpasa, Latin America’s largest producer of corn ethanol. By the end of 2022, this partnership is anticipated to have grown to the delivery of almost 1’000 pieces of equipment, including pumps, sealing systems, agitators and static mixers across three production plants in Brazil. Read the whole article.

-

Ensuring the right mixSulzer technology is playing a key role in Energiefabriek West, an innovative bio-power scheme in the Netherlands. The Rivierenland Water Authority in the Netherlands is investing in new infrastructure to improve the performance of its wastewater treatment systems while also reducing its impact on the environment. The utility is aiming to become energy neutral by 2030, and Sulzer technology is helping it to realize this goal.

-

Greening the desertThe plant, which was officially inaugurated by the country’s president Abdel Fattah El Sisi in April 2020, will produce enough clean water to irrigate 70’000 acres (283 square kilometers) of agricultural land.

-

Case studiesWherever fluids are pumped, mixed, controlled or applied, we are there. See how our solutions create value for customers and learn how we can make your pumping and mixing processes more efficient and profitable, safeguarding your production and ensuring lasting reliability.

Applications

-

Anaerobic digestionAnaerobic digestion requires temperature equalization and proper homogenization of the biomass to achieve a high gas production and to avoid sedimentation of organic matters. The surface crusts must be broken and prevention of foam must be managed if there are foaming tendencies. Sulzer can provide efficient and reliable Scaba agitators for digesters with high-efficiency propellers. Muffin Monster™ grinders upstream from the anaerobic digesters condition the sludge before digestion, improving the homogenization of the biomass and protecting the equipment downstream.

-

Bio-based applicationsBio-based chemicals, fuels and plastics are future building blocks to sustainability. For more than 40 years, we have been working hands-in-hands with technology providers and end-users to develop and improve efficiency and purity of processes devoted to the production of bio-based intermediates, products and fuels.

-

Bio-based process developmentFind and develop efficient process equipment for bio-based products in an agile way with Sulzer as your trusted partner.

-

BiodieselSulzer has develop a unique know-how based on its distillation technology to improve both clarity and purity of biodiesel. Single cut methyl esters can be used as solvents, intermediates for fatty alcohol and raw material for mono-ethanolamides.

-

Biological processThe target of the biological process in wastewater treatment is to remove organic, biodegradable substances via the metabolism of microorganisms and related biochemical processes.

-

Cellulose-based bioproductsExplore different ways cellulose-based bioproducts can be industrially processed. Sulzer employs and develops multiple application technologies for various feedstocks.

-

Chemical mixing - sludgeSometimes it is necessary to mix chemicals into the activated sludge before it enters the secondary sedimentation tank. For example, chemicals may be used to perform phosphorous removal on the effluent from the biological process. Many plants use chemicals to improve sludge thickening just prior to the sludge buffer tank.

-

Chemical mixing sewageChemicals must sometimes be mixed into the activated sludge before it enters the secondary sedimentation tank. Whenever this done, it is important to achieve an even distribution of the chemicals. Chemicals may be added to perform the chemical removal of phosphorous on effluent from the biological process. In other circumstances, chemicals such as cationic polyelectrolytes with a high molecular weight may be added to improve the quality and settling ability of flocs formed in the activated sludge process.

-

Chemical pulp fiber lineProven pumping, mixing and agitation solutions for your cooking, washing, screening, oxygen delignification, bleaching, and storage processes to ensure process reliability, high efficiency, and low operating costs.

-

Chemical recoverySulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements in your evaporation, recovery boiler, and white liquor preparation processes.

-

Chemical recyclingSuRe™ Technologies, is an integrated group of solutions that provide a sustainable path to transform end-of-life mixed plastic waste into high-value hydrocarbons

-

Chemicals for Pulp Paper and BoardTailored designs, features and material selections to meet the most demanding pumping, mixing, and agitation challenges in the production and preparation of chemicals, tall oil production, and lignin processing.

-

Coating and finishingA wide selection of highly efficient and reliable pumps and agitators for your pigment handling and color coating processes.

-

Downstream oleochemicalsThe majority of the downstream oleochemicals are concentrated or purified using thermal separation processes such as distillation. As an expert in thermal separation processes, Sulzer has developed unique hybrid processes using combinations of its most advanced separation know-how.

-

Fatty acidsSulzer fractional distillation is a well-established and recognized technology in the oleochemical industry to purify fatty acids mixtures to the right of fatty acid ratio(s) or to produce single cut fatty acid at the desired purity

-

Foam formingWe provide advanced equipment for executing and developing sustainable foam forming applications for wood, pulp, textiles, and bio-based products.

-

GlycerinGlycerin is a valuable by-product from the fatty acid and biodiesel value chains. Sulzer has developed a technology based on its proprietary distillation technology to refine glycerin to pharmaceutical grade glycerin and up to ultra high pure glycerin grades.

-

Industrial water and effluent treatmentSulzer has a deep knowledge in wastewater treatment, and with our wide product portfolio we can now offer energy-efficient and reliable solutions for your water collection, neutralization, flocculation, sedimentation, cooling, aeration, sludge storage, digestion, and dewatering processes.

-

Mechanical pulp lineSulzer’s ideal product portfolio for challenging pumping, agitation, and mixing operations in refining, grinding, CTMP, screening, reject handling, and bleaching processes.

-

Microfibrillated celluloseWe are actively involved in developing process equipment for microfibrillated cellulose. Our broad portfolio of industrial pumps, agitators, and mixers suit the specific needs of MFC.

-

Mine water managementSulzer offers a comprehensive portfolio of pumps and process equipment for abrasive and corrosive environments in mine water management applications.

-

MiningWhether on the surface or underground, the conditions in mines are harsh. Besides the mud, slurry, stones, and rocks, there are large volumes of water to remove in order to keep production moving. Our dewatering pumps are rugged and ready, taking on the toughest drainage and sludge removal.

-

Municipal clean water treatmentWhen planning new water treatment plants or upgrading existing ones, operating costs are as important as investment costs. Sulzer’s innovative pumps, mixers and compressors combine reliable treatment performance with superior energy efficiency.

-

Paper and board machine and systemsSulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements and for all types of liquids, making it ideal for challenging pumping, agitation, and mixing operations in stock preparation, PM approach system, broke system, white water system, vacuum system, condensate system, and shower water system processes.

-

Power plantsSulzer’s extensive product portfolio to maximize the performance and reliability of your solid organic fuel biomass power plant, solid industrial or municipal waste fuel biomass power plant, and liquid or gaseous organic fuel biomass power plant processes.

-

Pulp drying machineIncreased hydraulic excellence for your approach, cleaning, drying machine, vacuum, broke, and white water system processes.

-

Recycled fiber lineEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your pulping, screening & cleaning, flotation, washing, and bleaching processes.

-

SelectorThe purpose of the selector tank is to control and limit the growth of filamentous bacteria, and then to enhance the sedimentation ability of the sludge. Sulzer provides a number of solutions for creating optimal conditions in the selector.

-

Separation applicationsWe are a forerunner in the development of mechanical separation applications for bio-based raw materials. Our solutions produce ingredients in a very pure form, suitable for further processing.

-

Sludge buffer tankThe sludge buffer tank can be used for a variety of purposes. The most common application is the blending and homogenization of highly concentrated primary, secondary or digested sludge. The solution used to mix the sludge itself, or to mix the sludge with the dosed thickening chemicals, depends on the design and volume of the sludge buffer tank. Submersible mixer types ABS XRW and RW, as well as the agitator type Scaba, can be used to provide highly efficient mixing. Positive displacement, progressing cavity transfer pumps and Muffin Monster™ grinders are used for solids reduction and sludge transfer from sludge feed to sludge dewatering process.

-

Specialty estersSulzer has developed a unique process based on reactive distillation technology that combines both process steps into one, enabling, for the first time, continuous productions of isopropyl-esters.

-

Tertiary treatmentTreated wastewater may occasionally require further treatment. Local discharge rules may pose strict limits that cannot be fulfilled by even the most effective process, or a higher quality of effluent may be requested for its reuse. When tertiary treatment is needed, various levels of filtration can be applied, including very fine filtration. Often, however, a final step of mixing and aeration is sufficient to achieve the target. When this is the case, Sulzer's submersible mixer types ABS XRW and RW can be used, along with submersible aerator type ABS TA–TAK and disc diffuser system types ABS PIK, DS and Sucoflow.

-

Test equipment rentalRental equipment for textile and bio-based process development initiatives either at customer facilities or Sulzer’s development center.

-

Water supplyMeeting today’s challenges and high requirements within water intake, sedimentation, sludge treatment, fine screening, and water distribution processes.

-

Wood yardEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your debarking, washing, chipping, screening, and bark and waste streams handling processes.

Related links

Products and services

-

SALOMIX™ vertical agitatorsSALOMIX™ vertical agitators are used for mixing and agitating process liquids in demanding industrial applications.

-

PumpsAs one of the world's leading pump manufacturers, Sulzer provides a wide range of products for engineered, configured, and standard pumping solutions as well as essential auxiliary equipment. We are renowned for our state-of-the-art products, performance reliability and efficient solutions.

-

Service for mixers and agitatorsSulzer is the expert not only when it comes to supplying your equipment, but also when it comes to supporting it throughout its life cycle with over 140 years` experience. We make sure your mixer equipment runs smoothly with maintenance and repair on-site and support when you need it.

-

Service kitsWhen your equipment needs to be repaired you shouldn’t have to worry about spending valuable time searching for the right parts – or even worse, finding out that some small but vital parts are missing. With Sulzer service kits you get everything you need in one package.

-

Original pump spare partsOriginal spare parts machined to the correct tolerances and clearances give a perfect fit first time, every time. Our commitment to continuous improvement often allows us to supply parts with improved features, thus enhancing performance, extending equipment life, while reducing maintenance costs.

-

Tower management systemsSALOMIX tower management technology offers a wide range of systems for industrial tower applications. SALOMIX TES, SALOMIX GLI and SALOMIX VULCA systems help manage the demanding tower processes.

-

Industrial water treatmentWe provide extensive coverage of energy-efficient and reliable pumping, mixing, and aeration solutions for all industrial water treatment processes.

Industries

-

Food and beverageFood and beverage production relies on our pumping and mixing solutions. Special pumps and agitators have been developed for sugar, starch, and sweetener production. Separation equipment is often used in beverage manufacturing and our process technologies support purification and concentration.

-

Mining and metalsLong experience and detailed knowledge of metals and mining applications with different raw materials makes Sulzer a reliable pump supplier for these industries.

-

Oil gas and chemicalsHigh-performance pumps from Sulzer provide cutting edge solutions for the production, processing and transportation of hydrocarbons and CO2. Our technologies enable efficient separation processes for liquids and gas. We provide reliable services for compressors, turbines, motors, and generators through our global aftermarket network.

Talk or write to our experts to find your best solution.