- Suitable process equipment for various consistencies - up to 8% consistency

- Reliable partner for efficient scale-up

- Expertise in research and development

- Agile and fast development projects

Microfibrillated cellulose applications

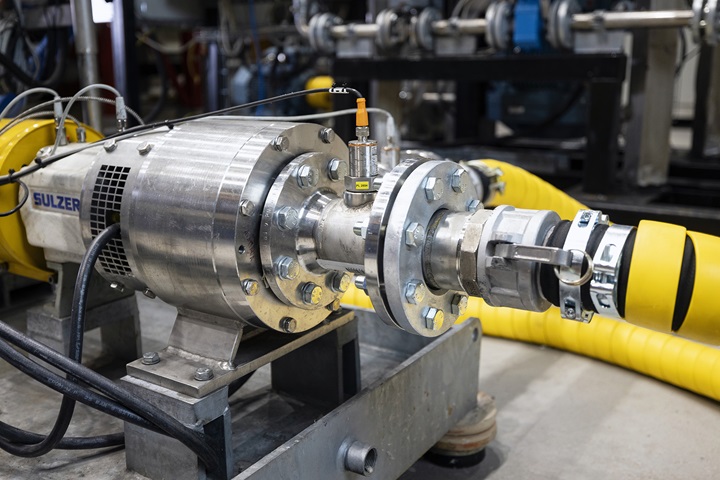

Reliable equipment for microfibrillated cellulose

Our industry leading solutions fulfill the application requirements, from loose slurry to highly viscous gel-like substance, up to 8% consistencies. Our portfolio offers technologies for stable suspensions and homogenization, without causing settling or agglomeration.

We facilitate producing MFC from biomass to replace fossil-based options

Using MFC as an enforcement the producers of paper, textiles, and packaging materials can enhance the quality and strength of their produce with favorable implications on profitability. We are also involved in researching the use of MFC for coatings, strengthening agents, and barrier coatings with partners working in various industries.

World-class research and development facilities

We actively investigate and develop new processes for products based on higher-value wood and bio-based raw materials. We offer efficient and scalable solutions for industrial processing and commercializing by combining the agility of a startup with the resources of an industrial market leader.

With the world's biggest full-scale research center for the pulp, paper, and board segment, we provide our partners with access to state-of-the-art facilities and resources for testing and refining their processes.

Rental test equipment

We offer a range of rental test equipment for our partners‘ process development purposes. The equipment can be used either in our full-scale development center in Kotka or at a customer’s site. Both continuous and batch-based processes equipment are accessible without sizeable investments into own testing, piloting, demo-batch, and pre-industrial batch equipment.

Trusted solutions provider

As an independent equipment supplier and a trusted application partner, we offer our clients peace of mind knowing that they are working with a reliable partner. We provide tailored solutions with two centuries of expertise in suspension transfer and treatment solutions in pulp, paper, and board processes combined with state of the art portfolio. Our process equipment is designed to meet even the most demanding needs, ensuring high-performance and efficient operations.