- Long and trusted experience in the pulp and paper and other industrial segments

- Excellent performance

- Reduced bacteria

- Improved and stable pulp quality

- Reduced chemical consumption

- Reduced air content

- Reduced crusting

- Suitable for the most demanding high-consistency tower applications in the pulp and paper industry

- Unique, patented and superior design features minimize life-cycle costs

- Quick and easy installation, safe operation, easy maintenance and service

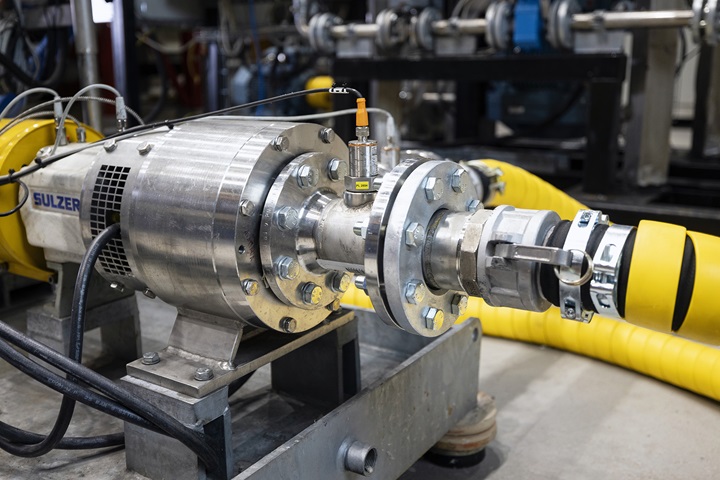

SALOMIX TES top entry spreader

Preventing channeling in storage and bleaching towers

Sulzer SALOMIX TES Top Entry Spreader spreads high-consistency fibrous slurries evenly on the top surface of the tower to control the flow in the upper, high-consistency part of the tower and to stabilize and homogenize the discharged fibrous slurry flow from the lower part of the tower.

- Medium and high consistency storage and bleaching towers

- Tanks and towers to reduce channeling and reduce air content

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

SALOMIX Tower Arrangement Demo

Main design features

- Versatile, reliable, high-efficiency spreading hydraulics and material options

- Reliable and heavy-duty bearing unit

Key characteristics

| Capacities | Capacity up to 600 l/s / 9 500 US gpm |

| Pressures | Pressure up to 3 bar / 43 psi as standard, for higher pressures as speacial |

| Temperatures | Temperature up to 180 °C / 355 °F |

| Performance range | Sulzer SALOMIX TES TOP Entry Spreader has large and tight hydraulic coverage to satisfy the most demanding requirements of pulp and paper tower applications. |

Documents

Brochures

Applications

-

Bio-based process developmentFind and develop efficient process equipment for bio-based products in an agile way with Sulzer as your trusted partner.

-

Cellulose-based bioproductsExplore different ways cellulose-based bioproducts can be industrially processed. Sulzer employs and develops multiple application technologies for various feedstocks.

-

Chemical pulp fiber lineProven pumping, mixing and agitation solutions for your cooking, washing, screening, oxygen delignification, bleaching, and storage processes to ensure process reliability, high efficiency, and low operating costs.

-

Chemical recoverySulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements in your evaporation, recovery boiler, and white liquor preparation processes.

-

Chemicals for Pulp Paper and BoardTailored designs, features and material selections to meet the most demanding pumping, mixing, and agitation challenges in the production and preparation of chemicals, tall oil production, and lignin processing.

-

Coating and finishingA wide selection of highly efficient and reliable pumps and agitators for your pigment handling and color coating processes.

-

Copper applicationsMaximize efficiency and durability in copper applications, while reducing energy costs and water consumption. With an advanced selection of materials for a comprehensive portfolio, Sulzer ensures reliable performance at minimized downtime, even in demanding environments.

-

Foam formingWe provide advanced equipment for executing and developing sustainable foam forming applications for wood, pulp, textiles, and bio-based products.

-

Industrial water and effluent treatmentSulzer has a deep knowledge in wastewater treatment, and with our wide product portfolio we can now offer energy-efficient and reliable solutions for your water collection, neutralization, flocculation, sedimentation, cooling, aeration, sludge storage, digestion, and dewatering processes.

-

Mechanical pulp lineSulzer’s ideal product portfolio for challenging pumping, agitation, and mixing operations in refining, grinding, CTMP, screening, reject handling, and bleaching processes.

-

Microfibrillated celluloseWe are actively involved in developing process equipment for microfibrillated cellulose. Our broad portfolio of industrial pumps, agitators, and mixers suit the specific needs of MFC.

-

Paper and board machine and systemsSulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements and for all types of liquids, making it ideal for challenging pumping, agitation, and mixing operations in stock preparation, PM approach system, broke system, white water system, vacuum system, condensate system, and shower water system processes.

-

Power plantsSulzer’s extensive product portfolio to maximize the performance and reliability of your solid organic fuel biomass power plant, solid industrial or municipal waste fuel biomass power plant, and liquid or gaseous organic fuel biomass power plant processes.

-

Pulp drying machineIncreased hydraulic excellence for your approach, cleaning, drying machine, vacuum, broke, and white water system processes.

-

Recycled fiber lineEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your pulping, screening & cleaning, flotation, washing, and bleaching processes.

-

Separation applicationsWe are a forerunner in the development of mechanical separation applications for bio-based raw materials. Our solutions produce ingredients in a very pure form, suitable for further processing.

-

Test equipment rentalRental equipment for textile and bio-based process development initiatives either at customer facilities or Sulzer’s development center.

-

Water supplyMeeting today’s challenges and high requirements within water intake, sedimentation, sludge treatment, fine screening, and water distribution processes.

-

Wood yardEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your debarking, washing, chipping, screening, and bark and waste streams handling processes.

Talk or write to our experts to find your best solution.