- Lowest energy consumption

- Compact, water pressure-tight design

- Provides high thrust and high flow capacity

- Self-cleaning propellers provides vibration-free operation

- Increased performance variations with an extended and wide duty range

- Superior reliability and long operating life

Flow booster type ABS XSB 900 to 2750

Exceptional low-speed efficiency

The complete answer to low-speed, highly energy efficient submersible mixing in a wide range of applications in industry and municipal treatment plants. This slow-speed submersible unit is available with integral IE3 Premium Efficiency motors ranging from 1.0 to 7.5 kW (7.4 to 10.1 hp) for gentle circulation and mixing of fluids.

- Providing a flow pattern in large tanks and open waters for mixing and stirring

- Wastewater treatment plants and industrial applications

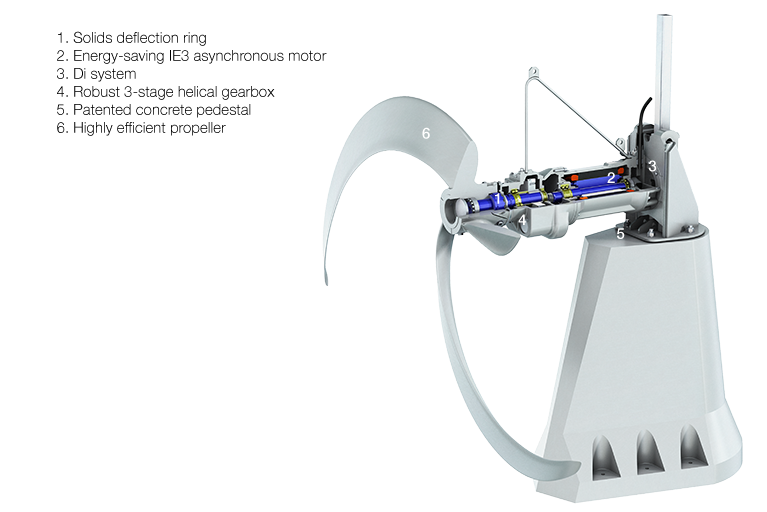

Main design features

- Designed for high reliability in challenging mixing applications

- Award-winning, patented high-efficiency propeller that offers up to 20% efficiency improvement over standard designs

- Patented concrete pedestal, designed to efficiently absorb vibration and improve reliability

- Fully-lockable patented coupling system allows easy lifting or lowering for inspection even when tanks are full

- Smart features such as seal monitoring inform preventative maintenance decisions

- Premium efficiency motors provide exceptional performance for gentle circulation as well as mixing of fluids in wastewater treatment plants and industrial applications

Key characteristics

| Maximum mixing flow | 6.2 m³/s (95,200 US gpm) |

| Maximum propeller diameter | 2,750 mm (9 ft) |

More information

- This slow-speed submersible unit is available with integral IE3 Premium Efficiency motors ranging from 1.0 to 7.5 kW (7.4 to 10.1 hp) for gentle circulation and mixing of fluids in wastewater treatment plants and industrial applications.

- Propellers for the XSB are designed for easy transport and installation. Most models are mounted complete, while the larger 3-blade models have a special design that allows them to be attached blade-by-blade. This facilitates transport and eliminates the need for special tools.

- The unit is connected to a concrete pedestal by an innovative coupling system which allows the unit to be raised and lowered for inspection even in filled tanks. The pedestal absorbs all dangerous vibrations, thus giving a long service life both for the machine and the installation.