- Foam forming

- Separation applications

- Micro-fibrillated cellulose

Cellulose-based bioproducts

- Pulp

- Wood

- Waste-biomass

- Textiles

Trusted solutions provider

We prioritize development and building partnerships. We work closely with leading institutions and industry partners to innovate and develop new processes for higher-value wood-based products. As an independent equipment supplier and a trusted application partner, Sulzer offers clients peace of mind knowing that they are working with a reliable partner.

Two centuries of expertise in suspension transfer and treatment solutions in pulp, paper, and board processes combined with a state of the art portfolio, Sulzer provides tailored solutions. Our process equipment is designed to meet the needs, ensuring high-performance and efficient operations.

The fibrous material from wood, straws or other biomass gets pulped and turned into foam with suitable substances and aeriation method.

The optimal aeriation method is selected based on whether the process is continuous, or batch based. Online aeration with a mixer pump fits a continuous process, and mixing in a container suit batches.

Because we know the flow characteristics of the foam at various consistencies we can offer the right technology for foam generation, and for furthering it into foam forming, coating and molding applications. With application-specific process equipment extremely homogenous foam is turned into everyday items.

The applications are designed to dissolve pulp, polymeric hemicellulose and lignin from biomass. The technology offers a more sustainable way to use wood, agro-based materials, and bio-waste as feedstock in industrial manufacturing.

The process equipment selection is based on flow-behavior of the substances and requires a range of devices suitable for homogenization, agitation, mixing, and pumping of fibrous substances.

Through a fibrillation process the cellulose fibers are separated into a three-dimensional network of microfibrils with a large surface area. These entangled fibrils are called micro-fibrillated cellulose.

The construction of the process is dictated by how finely the fibrils need to be grinded. Suitability for high-viscosity suspension is required from pumping and agitation equipment.

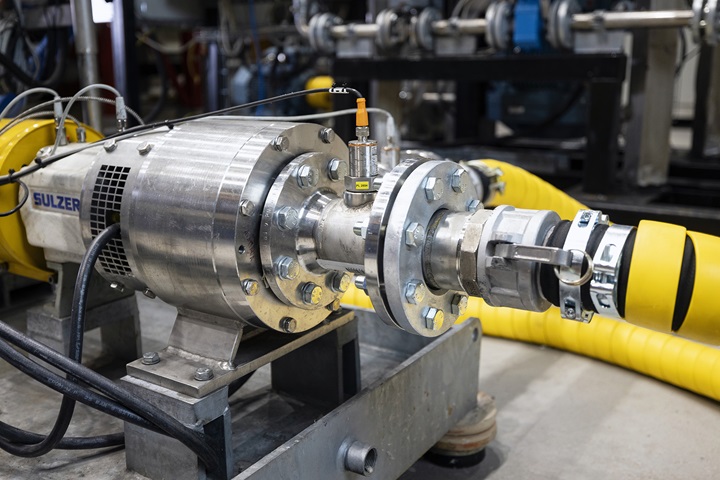

Sulzer offers a broad range of rental test equipment for our partners‘ process development purposes. The equipment can be used either in our full-scale development center in Kotka or at a customer’s site.

Both continuous and batch-based processes equipment are accessible without sizeable investments into own testing, piloting, demo-batch, and pre-industrial batch equipment.