- Long and trusted experience in the pulp and paper and other industrial segments

- Excellent performance

- Suitable for the most demanding industrial applications

- Unique, innovative and superior design features minimize life-cycle costs

- Quick and easy installation, safe operation, easy maintenance and service

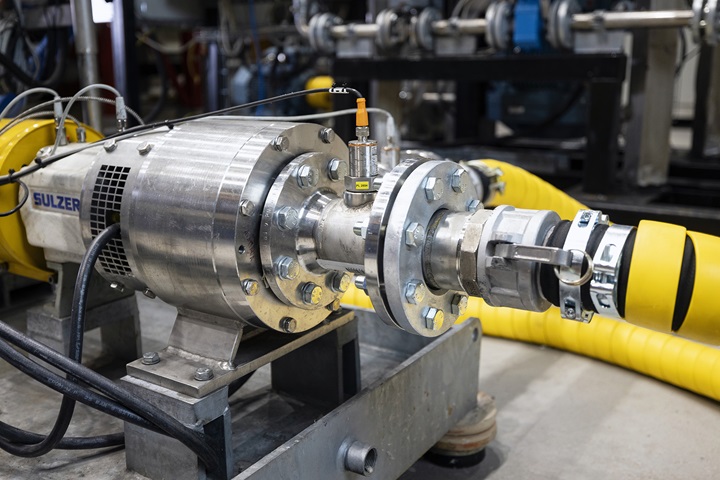

SX chemical mixer

Brings excellence into the mixing

SX dynamic chemical mixers are used for mixing gases or chemicals into pulp or other type of process liquids in demanding industrial applications. SX mixer ensures a homogenous mixing result, high process reliability, high efficiency as well as low operating and chemical costs.

- In-line mixer for gases

- SX chemical dynamic in-line mixer is used for mixing liquid chemicals, gases and steam into

- Fibrous slurries

- Clean and lightly contaminated liquids

- Viscous liquids

- Non-fibrous slurries

- Mostly used in mixing chemicals in pulp bleaching line

Main design features

- Versatile, reliable, high-efficiency mixing hydraulics and a variety of material options

- Innovative shaft sealing solutions for reliable operation and reduced costs

- Reliable and heavy-duty bearing unit

Key characteristics

| Capacities | Up to 550 l/s / 8’700 US gpm |

| Pressures | Up to 25 bar / 360 psi |

| Temperatures | Up to 180 °C / 355 °F |

| Discharge sizes |

From from 150 mm / 6 in to 350 mm / 14 in |

| Maximum speed of rotation | Up to 1 800 rpm |

Documents

Brochures

-

SX Dynamic Chemical MixerpdfLanguages:

-

Medium-consistency technologypdfLanguages:

Technical articles

Applications

-

Bio-based applicationsBio-based chemicals, fuels and plastics are future building blocks to sustainability. For more than 40 years, we have been working hands-in-hands with technology providers and end-users to develop and improve efficiency and purity of processes devoted to the production of bio-based intermediates, products and fuels.

-

Bio-based process developmentFind and develop efficient process equipment for bio-based products in an agile way with Sulzer as your trusted partner.

-

BiodieselSulzer has develop a unique know-how based on its distillation technology to improve both clarity and purity of biodiesel. Single cut methyl esters can be used as solvents, intermediates for fatty alcohol and raw material for mono-ethanolamides.

-

Cellulose-based bioproductsExplore different ways cellulose-based bioproducts can be industrially processed. Sulzer employs and develops multiple application technologies for various feedstocks.

-

Chemical pulp fiber lineProven pumping, mixing and agitation solutions for your cooking, washing, screening, oxygen delignification, bleaching, and storage processes to ensure process reliability, high efficiency, and low operating costs.

-

Chemical recoverySulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements in your evaporation, recovery boiler, and white liquor preparation processes.

-

Chemical recyclingSuRe™ Technologies, is an integrated group of solutions that provide a sustainable path to transform end-of-life mixed plastic waste into high-value hydrocarbons

-

Chemicals for Pulp Paper and BoardTailored designs, features and material selections to meet the most demanding pumping, mixing, and agitation challenges in the production and preparation of chemicals, tall oil production, and lignin processing.

-

Coating and finishingA wide selection of highly efficient and reliable pumps and agitators for your pigment handling and color coating processes.

-

Copper applicationsMaximize efficiency and durability in copper applications, while reducing energy costs and water consumption. With an advanced selection of materials for a comprehensive portfolio, Sulzer ensures reliable performance at minimized downtime, even in demanding environments.

-

Downstream oleochemicalsThe majority of the downstream oleochemicals are concentrated or purified using thermal separation processes such as distillation. As an expert in thermal separation processes, Sulzer has developed unique hybrid processes using combinations of its most advanced separation know-how.

-

Fatty acidsSulzer fractional distillation is a well-established and recognized technology in the oleochemical industry to purify fatty acids mixtures to the right of fatty acid ratio(s) or to produce single cut fatty acid at the desired purity

-

Foam formingWe provide advanced equipment for executing and developing sustainable foam forming applications for wood, pulp, textiles, and bio-based products.

-

GlycerinGlycerin is a valuable by-product from the fatty acid and biodiesel value chains. Sulzer has developed a technology based on its proprietary distillation technology to refine glycerin to pharmaceutical grade glycerin and up to ultra high pure glycerin grades.

-

Industrial water and effluent treatmentSulzer has a deep knowledge in wastewater treatment, and with our wide product portfolio we can now offer energy-efficient and reliable solutions for your water collection, neutralization, flocculation, sedimentation, cooling, aeration, sludge storage, digestion, and dewatering processes.

-

Mechanical pulp lineSulzer’s ideal product portfolio for challenging pumping, agitation, and mixing operations in refining, grinding, CTMP, screening, reject handling, and bleaching processes.

-

Microfibrillated celluloseWe are actively involved in developing process equipment for microfibrillated cellulose. Our broad portfolio of industrial pumps, agitators, and mixers suit the specific needs of MFC.

-

Paper and board machine and systemsSulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements and for all types of liquids, making it ideal for challenging pumping, agitation, and mixing operations in stock preparation, PM approach system, broke system, white water system, vacuum system, condensate system, and shower water system processes.

-

Power plantsSulzer’s extensive product portfolio to maximize the performance and reliability of your solid organic fuel biomass power plant, solid industrial or municipal waste fuel biomass power plant, and liquid or gaseous organic fuel biomass power plant processes.

-

Pulp drying machineIncreased hydraulic excellence for your approach, cleaning, drying machine, vacuum, broke, and white water system processes.

-

Recycled fiber lineEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your pulping, screening & cleaning, flotation, washing, and bleaching processes.

-

Separation applicationsWe are a forerunner in the development of mechanical separation applications for bio-based raw materials. Our solutions produce ingredients in a very pure form, suitable for further processing.

-

Specialty estersSulzer has developed a unique process based on reactive distillation technology that combines both process steps into one, enabling, for the first time, continuous productions of isopropyl-esters.

-

Test equipment rentalRental equipment for textile and bio-based process development initiatives either at customer facilities or Sulzer’s development center.

-

Water supplyMeeting today’s challenges and high requirements within water intake, sedimentation, sludge treatment, fine screening, and water distribution processes.

-

Wood yardEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your debarking, washing, chipping, screening, and bark and waste streams handling processes.

Case Studies, articles and news

-

Sulzer to supply pumps and mixers to the new bioproduct mill in Kemi, FinlandMarch 24, 2021Metsä Fibre, part of the Finnish forest industry company Metsä Group, and Sulzer Pumps Finland have signed an agreement for the supply of process pumps, medium-consistency pumps and mixers for the main processes of the bioproduct mill that will be built in Kemi. The delivery will include several hundred devices.

-

Trusted partner for new wood-based processesSulzer is a company with long and solid experience and proven expertise in several important customer segments. Pulp, board and paper processes and applications as well as new ones based on wood raw materials represent high-priority commitment and partnership areas for the business and product development organization. Read the whole article.

-

Case studiesWherever fluids are pumped, mixed, controlled or applied, we are there. See how our solutions create value for customers and learn how we can make your pumping and mixing processes more efficient and profitable, safeguarding your production and ensuring lasting reliability.

Talk or write to our experts to find your best solution.